e-breathe Respiratory Protection Test Heads – Precision Test Heads for Respiratory Interfaces & PPE

PPE test heads for standard testing, research, and quality control

Respiratory protection test heads are specialized test bodies developed for the standards-compliant evaluation of respiratory protection systems. They serve as a standardized interface onto which respiratory interfaces such as masks, hoods, helmets, or protective suits are mounted. This enables precise, reproducible testing in accordance with the requirements defined in the relevant product standards.

Via integrated connection ports, the test heads can be connected to breathing machines, lung simulators, or mask testing devices. This creates realistic test conditions that allow for reliable assessment of leak tightness, breathing resistance, and other safety-critical parameters.

Two types of test heads are distinguished:

• Sheffield Test Head: A standardized test head for respiratory protective devices, widely used across Europe. It represents a single, uniform head size and is used as a reference for testing according to European standards.

• ISO Test Head acc. to ISO 16900-5: A standardized test head system specifically designed for testing respiratory protective equipment. Unlike the Sheffield test head—which represents only one standard size—the ISO standard defines a set of five different head sizes based on real anthropometric data of the global population. Manufacturers are required to test their respiratory protection products across all relevant sizes to ensure full standards compliance.

Product Description & Technical Configuration

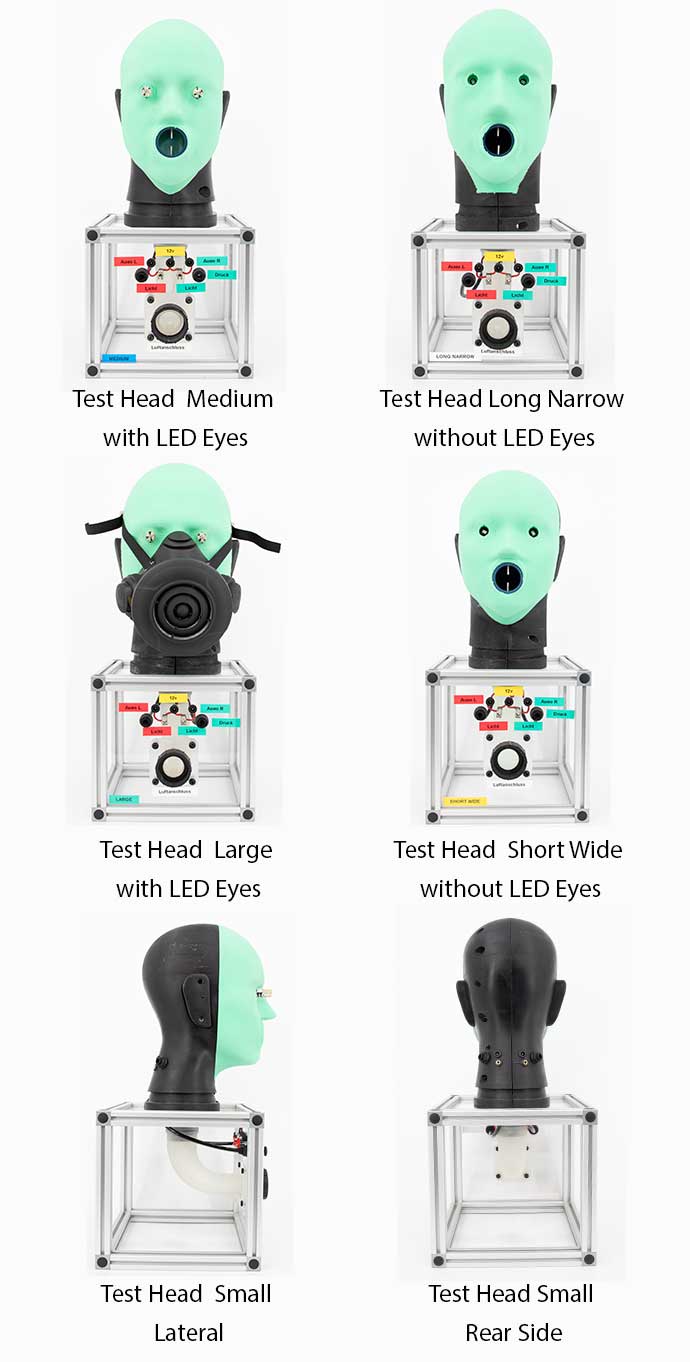

The ISO test heads developed by e-breathe Safety meet the requirements of ISO 16900-5 (Respiratory protective devices – Test methods) and are available in five head sizes: Small (S), Short-Wide (SW), Medium (M), Long-Narrow (LN), and Large (L). The ISO test heads provide practice-oriented functionality for research, development, and quality control.

Connections & Sensor Technology

- Trachea with EN 148-1 round threaded connection for test equipment

- Two measurement ports in the mouth/trachea area (e.g., for CO₂ and pressure measurement)

- Two additional pressure measurement points in the eye region

LED Field of Vision Testing

Standard integrated, replaceable LED eyes, individually controllable

Designed for field of vision testing acc. to ISO 16900-11

Realistic Material Properties

Front section with skin-like elastomer surface (Shore hardness 20; additional hardness levels available on request)

Rear section made of durable, leak-tight resin, two-piece and screwed—easy to open for repair and upgrades

Expansion & Customization Options

Interfaces for optional hearing devices in the ears for hearing tests acc. to ISO 16900-14

Soft sealing surface at the neck, with optional additional seal for hood testing

Replaceable base plate for mounting on static or dynamic test torsos

Leakage & Tightness Testing

Thanks to the fully leak-tight design, the test heads are also suitable for testing in leakage chambers.

Technical Highlights

- Five sizes: S, SW, M, LN, L

- EN 148-1 round threaded connection

- Measurement ports for CO₂ and pressure in the mouth/trachea area

- Pressure measurement at both eyes

- Replaceable LED eyesindividually controllable

- Elastomer skinavailable in various hardness levels

- Replaceable earswith optional integrated hearing devices

- Neck sealing optionfor hood testing

- Compatible with test torsosacc. to ISO 16900-5

Areas of Application

- Test laboratories & certification institutes

- Research & development

- Production & quality control

- Maintenance & service

Standards & Guidelines

- ISO 16900-5 — test heads

- ISO 16900-11 — field of vision testing

- ISO 16900-14 — noise emission / hearing tests

- Additional standard tests: ISO 16900-2, -8, -9, as well as EN 13274-1 and EN 136

Functions & Applications in Detail

Field of Vision Test (ISO 16900-11)

Thanks to the integrated LED eyes, field of vision tests acc. to ISO 16900-11 can be performed with high precision. The LEDs are individually controllable, allowing the simulation of different viewing angles. During testing, the Visual Field Score (VFS) is determined, representing the effective field of vision provided by a respiratory mask or hood.

Leakage Test (ISO 16900-1 / EN 13274-1)

Thanks to their fully leak-tight construction, the test heads are also suitable for use in leakage chambers. They are mounted on a test torso, which uses a breathing machine to realistically simulate human respiration. During testing, inward leakage is measured—i.e., the amount of ambient air entering the respiratory protection system. This measurement is a key parameter for determining the protection class of masks and hoods.

Hearing Test / Noise Emission (ISO 16900-14)

The test heads can optionally be equipped with replaceable ears including integrated hearing devices. This enables precise measurement of noise emissions from respiratory protection systems directly at the test head. At the same time, it can be verified whether acoustic warning signals are reliably perceived—a critical safety factor in real-world use.

Leak Tightness Test (EN 136)

The test heads can be directly connected to mask testing devices, enabling leak tightness testing of full-face masks acc. to EN 136. This procedure ensures that the respiratory protection system seals reliably and that no external air enters the mask through leaks.

CO₂ Test, Breathing Resistance & Volume Flow

The test heads feature precisely integrated measurement ports in the mouth and trachea area, enabling several safety-critical functional tests:

• CO₂ content of inhaled air (ISO 16900-9): Assessment of breathing air quality for the user.

• Breathing resistance measurement (ISO 16900-2): Determination of the extent to which the respiratory protection system affects breathing.

• Volume flow measurement (ISO 16900-8): Verification of airflow performance and efficiency of the respiratory protection device.